Car construction and specification plays a role

Earlier, I mentioned the court cases for some high-end vehicle manufacturers that were about brake noise in brand new vehicles.

How can this be? Most people would agree that an Audi Q7 is a brilliant car, very luxurious and you would expect comforts over and above most other cars. However, recently Audi was taken to court (in the US) by a disgruntled owner who thought the brake squeal in his brand-new car was over the top, so wanted compensation! You can bet the very same friction material and similar disc spec has been used on thousands of cars from the VW Group, so why the noise in this car? The court case didn’t proceed, and we won’t go into details, but the point is that brake noise is a tricky issue that even the world’s most technologically advanced vehicle makers encounter from time to time.

The other thing to mention is customer expectation. The court case with Audi may involve a customer who is overly sensitive and unaware of the noises high performance cars make, that standard luxury cars don’t? We don’t know that, but it’s a consideration.

Some of the possible contributing factors that may cause the noise will be:

Opposed pistons vs Sliding calipers

Brake calipers come in various specifications, but the most obvious difference most notice is whether the caliper is a ‘slider’ or not. Many OEM supplied brakes are sliding calipers where the caliper has 1 or more pistons on the ‘inboard’ side only. Opposed piston calipers are a bigger structure than sliders and use pistons on the inner and outer of the caliper. Most tend to name them based on how many pistons they have – 4 pot, 6 pot etc.

The thing is – you are more likely to have brake noise in the opposed piston calipers. Sliders tend to have a certain amount of ‘give’ in them when in use which can have a kind of suppression effect on the vibration, whereas the 4 pot fitted to your Lancer Evo is quite stiff, which means it is less likely to ‘absorb’ any vibration and will pass it ‘down the line’ until that vibration becomes noise. Once again though, this is not a fixed rule as you can also have brake noise in sliders.

The other point to note here is that opposed piston calipers are more likely to be fitted to performance cars used at the track, so are more likely to have higher friction brake pads fitted, so possibly more likely to produce brake noise.

Brake Mass

Because the noise is a result of vibration, the ‘heavier’ the brake – the less likely it will vibrate. Try to imagine a very large diameter, thin disc that also has a low-mass vane design, versus a small disc that is very thick and heavy. The large, light disc is much more likely to be unstable when the brakes are applied, therefor more likely to vibrate. There is a balance to be found in brake design, and this is what manufacturers strive to achieve to supply performance, reliability and comfort.

This is also relevant to the parts surrounding the brake such as dust shield, suspension connectors, knuckle, and connection points on the chassis.

Disc metallurgy

This is an area that is controversial, because all disc manufacturers will tell you they have manufactured a disc that is reliable and not the cause of any issues. However, just like the caliper rigidity, the same type of result can be had when the disc rotor is kind of ‘too good’.

When the disc is made from high quality material designed to be very rigid with no ‘give’, they offer the driver excellent pedal feel and, in many cases, will wear and perform very well. This is the idea of a high-performance disc so if you have that, you have got what you paid for!

However, when it comes to brake noise caused by friction, this can be detrimental. When used with higher friction pad compounds, this disc may be more likely to vibrate than a low-quality disc that has more ‘give’. Now I’m not recommending you buy inferior discs, but just be aware that buying the best performing brake discs doesn’t mean you are buying the lowest noise.

Slotted and/or Drilled brake discs

This one is up for debate. Does a drilled or slotted (or both in some cases) create more chance of brake noise? Most would argue yes. The extra leading edges running across the edge of the friction material on the brake pads may increase the friction, therefor the chances of squeal. However, many cars have slotted or drilled discs without any noise issues, so it is hard to lay blame on the rotor.

How does brake pedal pressure affect brake noise?

Pedal pressure is very relevant to brake performance. It is also relevant to brake noise. How?

If you happen to have a car with brake squeal issues (whether it’s a brand spanking new Q7 or a 20yo Evo) you will most likely notice the squeal more at low speeds whilst using low brake pedal pressure. Like when you stop gently at traffic lights, or pull into the drive-thru at Macca’s…

Generally, the harder you press, the lower the noise. The reason for this is that your brake pads are ‘clamped’ harder against the disc face therefor reducing the ability for the brakes to vibrate. If you reduce pedal pressure, the system becomes a little more ‘free’ to vibrate and possible create squeal.

How to fix or reduce brake noise

In some cases it may be an easy fix, and in some cases this problem requires a specification change such as pad material or disc spec. Let’s run through some of the common ‘fixes’ for brake squeal – assuming the issue is not worn-out pads or foreign material in the brake system.

Anti-squeal Shims

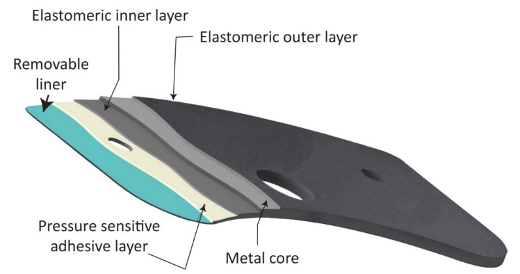

Normally designed specifically for the pad shape and fix to the back of the pads. This sits them between the brake pad and the caliper pistons where they act like an insulator to try to reduce the transfer of vibration from the pad/disc face through to the caliper.

As the name suggests, these are shims fitted to the brake pads to help prevent brake squeal. These parts are normally designed specifically for the pad shape and fix to the back of the pads. This sits them between the brake pad and the caliper pistons where they act like an insulator to try to reduce the transfer of vibration from the pad/disc face through to the caliper.

Shims come in several materials and specs, but the most effective style tends to be a multi-layered composite of materials such as galvanised steel, stainless steel, rubber, fibre and others. Most of these shims will have some form of location clip to keep then in place, as well as an adhesive back to fix them to the backing plate securely.

It is worth noting here that in some cases shims can change the pedal feel slightly due to the small amount of compressibility of the shim itself. In most cases it is un-noticeable but this is one of the reasons we do not use shims in competition cars.

Some shims are designed to effectively ‘cock’ the caliper piston slightly when they are applied to the shim. This is done by having the shim only cover half of the piston. See picture below where the red circle represents the approximate location of the piston contact.

Anti-Squeal compound / grease

This product (available from a multitude of suppliers such as Bendix, CRC etc) and is another option to use on the backing plate. This can be used in conjunction with shims well, for the extreme cases! The compound goes on like a grease, but firms up to become a rubbery substance which is designed to dampen vibration, therefore noise.

Service calipers

Calipers are an important part of the issue because they are the part that is connected to the pads! Pretty obvious I know, but what is less obvious is the fact that worn piston seals will increase the likelihood of brake squeal because of the increased contact between the pistons and caliper body.

Sliding calipers have sliding pins that the body of the caliper is supported, and ‘slides’ when the brakes are used. These pins should be lubricated with high temp grease suitable for the job. This not only assists with smooth caliper operation, but also reduces the metal-metal contact in the caliper.

Chamfer on pad material

This solution is a little like the brake disc slots argument in that there is no real evidence to prove it works to reduce friction. The concept is that the chamfer on the leading edge of the pads reduce the leading edge of the friction material where it is in contact with the disc, hence reducing the possibility of noise. However, in most cases it is the actual pad material creating the friction not so much the edge of the pads.

However, there is no downside to trying this solution, so it is always worth a go. In some cases, it will help.

Replace parts

This is the last resort! If you have exhausted all the options available to you and don’t want to put up with any brake noise you may need to change parts to a more standard pad compound and disc specification that is designed for street use only. Many people who use their car for track days or enthusiast activity keep their ‘good’ set of pads aside and install for the weekend. Then revert to the road pads for the daily grind to and from work.

To conclude…

The risk of brake noise occurring does increase as you improve the performance of your car’s brakes. However, we have to remember that all modification to standard cars will a side effect of some sort. It is also worth remembering that MOST cars don’t make brake noise even when using high friction brakes.